India is well known for its tradition and so is its tradition of cooking with earthenware. It’s an age-old concept that has deserted with time. This golden concept was then washed over by modernization as we moved to the stainless steel or bone china or melamine era.

One can get a rare antique of an earthen pot in a few homes these days, the reason being its natural benefits. Earthenware has tremendous health benefits. Cooking food with it embarks nutritional value of the clay to the food. The porous material of clay helps water seep through it, letting you enjoy the mildly cool water. Not only this, but the mineral composition and porous nature of clay pots and other clay products also accentuate the flavour of the food we eat.

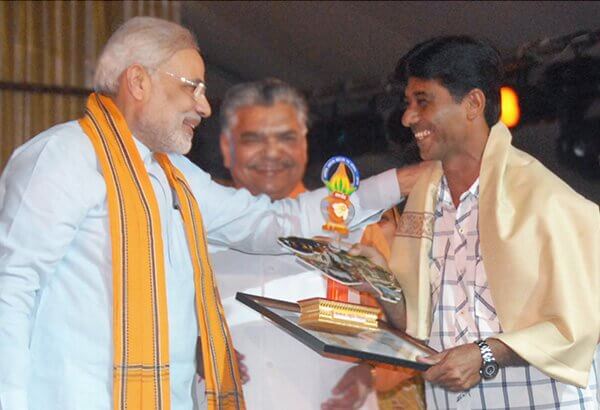

Mitticool is all about re-growing these rich lost roots of Indian culture into the modern environment. Mitticool prides its initiative on preserving our old culture. We produce clay products and clay pots that lead to a healthy, natural life and also revive our rich tradition.